A single thread can be the difference between a system that holds pressure and one that leaks.

The pipe threads have different variants. And when it comes to sealing fluids under high pressure, even a tiny flaw can cause trouble.

Hydraulic setups demand more than just “tight enough.” They need threads that hold under stress, without relying on tape or paste to do the sealing. That’s where the battle between NPT and NPTF threads begins.

In the blog, we’ll discuss the same.

Why pipe thread seal matters in high-pressure systems

Hydraulic systems deal with serious pressure. If air gets in or fluid leaks out, efficiency drops. Even worse, contamination or pressure loss can damage other parts.

So, thread quality is not a thing a machinist can ignore. A tiny leak in a fitting thread can turn into a system-wide problem, especially in systems that cycle often or run nonstop.

This is why picking the right thread type and the right tap to cut those threads is critical.

The core difference between NPT and NPTF threads

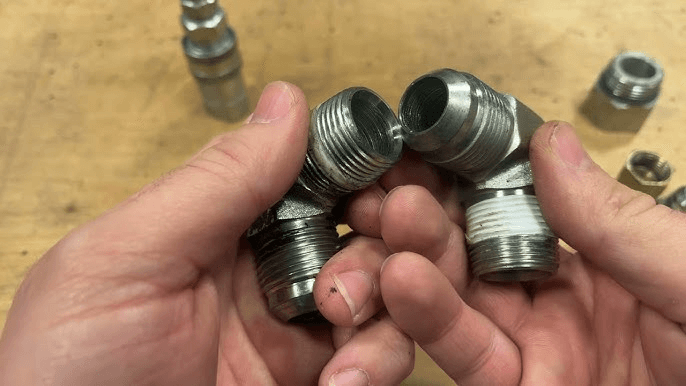

Both NPT and NPTF are tapered threads. They look nearly the same from a distance. But they don’t behave the same once installed.

NPT threads have a gap between the roots and crests of the mating parts. That gap is why they need a sealant. Thread tape or paste fills that space to stop leaks.

NPTF threads are cut differently. Their design closes the gap. When two NPTF parts are threaded together, metal-to-metal contact forms a dry seal.

That’s the main difference.

Why NPT threads require sealants

NPT was never made to seal without help. The thread form is not designed to crush into the mating part. It’s designed to pull tight and rely on thread compound to close the gaps.

Even if you crank down hard on an NPT fitting, it’ll likely still leak without a sealant. At low pressures, you might get away with it. At high pressures? Not worth the risk.

That’s why, if you’re cutting NPT threads using pipe taps, you must be consistent with sealant use. It becomes part of the sealing method, not just an add-on.

How NPTF threads seal without sealants

This is where things get interesting.

NPTF threads are made to seal dry. The crests of one part press tightly into the roots of the other.

But that seal doesn’t just happen magically. It depends heavily on how the threads were cut.

Using a worn-out tap won’t give you a true NPTF thread. You might still get something that fits. But the dry-seal property? Gone.

That’s why pipe taps for NPTF must be sharp, clean, and within spec. Tapping depth also matters more here than it does with NPT.

Tolerances and tap geometry differences that matter

The tap geometry for NPTF is tighter.

With NPT taps, you can get away with small deviations. But NPTF threads must be precise. Root flats need to be sharp. Truncation and crest height can’t be off by much.

Even the pitch diameter tolerance is stricter in NPTF taps. That’s because any mismatch between threads will leave a gap, and you lose the dry-seal feature.

This is why you’ll often find dedicated NPTF pipe taps used only for critical sealing applications. They cost more, but they cut threads that don’t leak.

If you mix up the taps or use general-purpose ones, you might not know anything’s wrong until the leak shows up.

How pipe tap selection affects thread fit

Thread form depends entirely on the tap. If you’re using an old tap or one that’s been reground poorly, it can cut undersized threads. Those threads may look fine. But they won’t hold up under pressure.

NPTF threads especially demand a correct tap. Even using an NPT tap and then trying to seal the joint dry won’t work. The shape is just different.

That’s why shops often stock both types of pipe taps. NPT for general use. NPTF for critical applications like hydraulics or fuel systems.

And yes, it also means your tap drill size needs to be matched carefully. One size doesn’t fit all, even with closely related types.

Conclusion

Choosing between NPT and NPTF threads depends on sealing performance. For leak-proof hydraulics, NPTF offers cleaner, more reliable results if done right. But it demands precision and proper tools. NPT is easier to work with, but relies on sealants.

Understand your system’s needs, and match it with the right tap and thread type. That’s how you stop leaks before they start.

Cassia Rowley is the mastermind behind advertising at The Bad Pod. She blends creativity with strategy to make sure ads on our site do more than just show up—they spark interest and make connections. Cassia turns simple ad placements into engaging experiences that mesh seamlessly with our content, truly capturing the attention of our audience.